-

All Products

-

Trapezoid Roof Sheet Forming Machine

-

Corrugated Sheet Roll Forming Machine

-

Glazed Roll Forming Machine

-

Color Steel Bending Machine

-

Square Ridge Tile Machine

-

High Altitude Roll Forming Machine platform

-

Downspout Roll Forming Machine

-

Cable Tray Roll Forming Machine

-

Standing Seam Roll Forming Machine

-

Cold Roll Forming Machine

-

Double Layer Roll Forming Machine

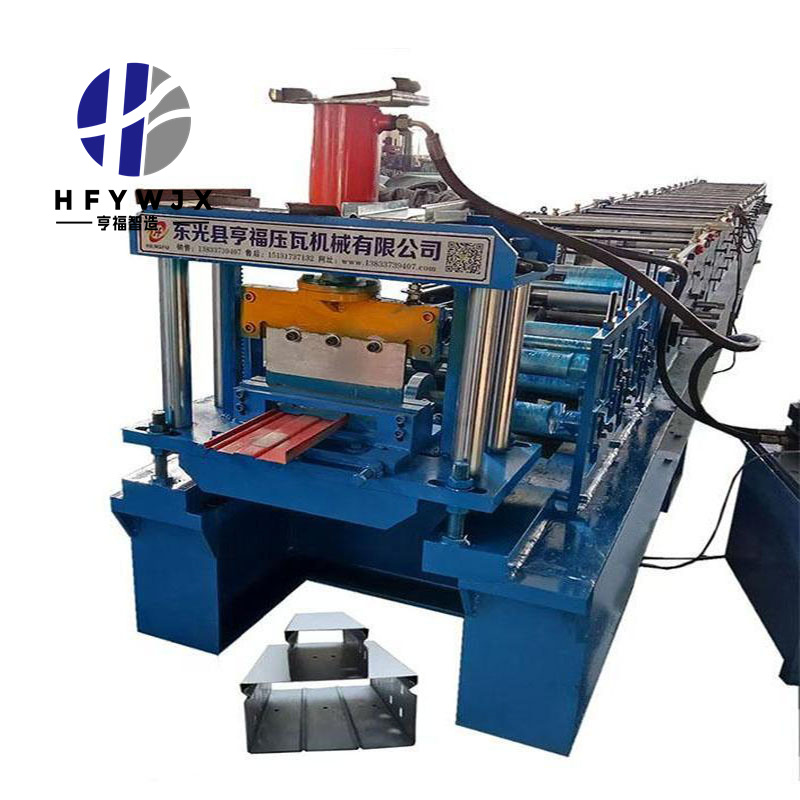

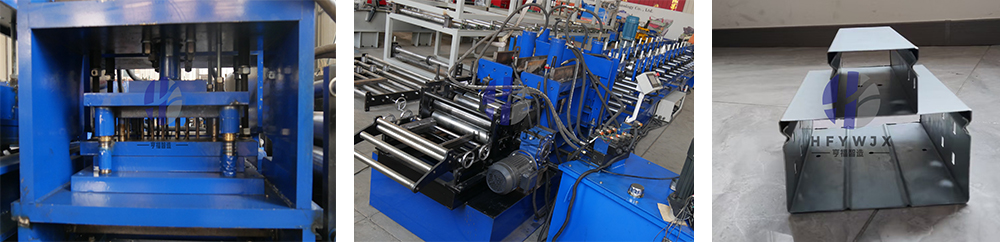

Cable Tray Roll Forming Machine

The cable tray forming machine is used to produce cable trays related to the electrical industry. The finished products are ladder-shaped bridges and trough-type bridges. It is often used to build photoelectric communications, computer room

The cable tray forming machine is used to produce cable trays related to the electrical industry. The finished products are ladder-shaped bridges and trough-type bridges. It is often used to build photoelectric communications, computer room electrical, circuits, cable equipment and other fields. In the future, with the application of intelligent technology and the development of industrial automation, cable tray forming machines will gradually become an important equipment in the cable tray production industry.

"Inlet guide"

① Positioning roller: adjust the position of both ends to match the feed width.

②Guide roller: The upper and lower round roller design makes the feeding process smoother.

③ Machine base tie rod: φ20# round steel to increase the rigidity on both sides of the wall panel.

"Roller assembly"

①Spindle diameter: φ80/95mm, 45# round steel.

②Roller material: heat treatment, hard chrome plating after finishing, mirror polishing.

③Cold bending: the process of cold bending the material roll one by one.

"Cut after forming"

① Cast iron knife holder: obvious shock absorption effect and strong impact resistance.

②Blade material: Cr12Mov, shearing life exceeds 1 million times.

③Rear scissor frame: Q235 steel plate, annealed after rough milling, and finished.

With the rapid development of power engineering, construction engineering and communication engineering, the demand for cable trays is gradually increasing. Traditional handmade cable trays are inefficient and unable to meet the growing market demand. The emergence of cable tray forming machines has solved this problem. At present, cable tray forming machines already have a series of core technologies such as high-speed forming, automatic cutting, and automatic welding, which have greatly improved the production efficiency of cable trays.

In the future, with the rapid development of intelligent technologies such as artificial intelligence and the Internet of Things, cable tray forming machines will be further upgraded. Adopt an intelligent control system to realize remote monitoring and fault diagnosis of equipment, improving production efficiency and stability. At the same time, the application of machine vision and data analysis technology will be strengthened to realize real-time monitoring and optimization of the cable tray production process and improve product quality and consistency.

Our company can produce various types of tile pressing machine products, and the roll forming plate types are diverse.

Q1:Are you a manufacturer?

A1:Yes absolutely. Welcome a lot for your visiting to us.

Q2:Do you have after-sale support?

A2:Yes, we're always here for giving you advice and support for technical details since we have senior technician.

Q3:Is there quality control when manufacturing the lines?

from laying off the raw material, processing the rollers and the other parts, make treatment on the roller surface and shaft, assembling, testing and packaging.

Q4:What's your strength comparing to the other supplier?

A4:We'll supplying you the best quality and service. We'll give you good advise beyond your requirements. The lines are easily for installation and with low mantenance requirements.

Q5:- Any other service?

A5: We can manufacture, design, installation and debug various roll forming machines including standard and customized machines.

It is free to assemble machine and train your works, but the buyer should pay for the round-trip airplane ticket, and arrange

accommodation during that time.