-

All Products

-

Roll Forming Machine

-

Corrugated Sheet Roll Forming Machine

-

Glazed Roll Forming Machine

-

Color Steel Bending Machine

-

Square Ridge Tile Machine

-

High Altitude Roll Forming Machine platform

-

Downspout Roll Forming Machine

-

Cable Tray Roll Forming Machine

-

High-speed Metal Roofing Machine

-

High-working Metal Roofing Machine

-

High-speed Roll Forming Machine

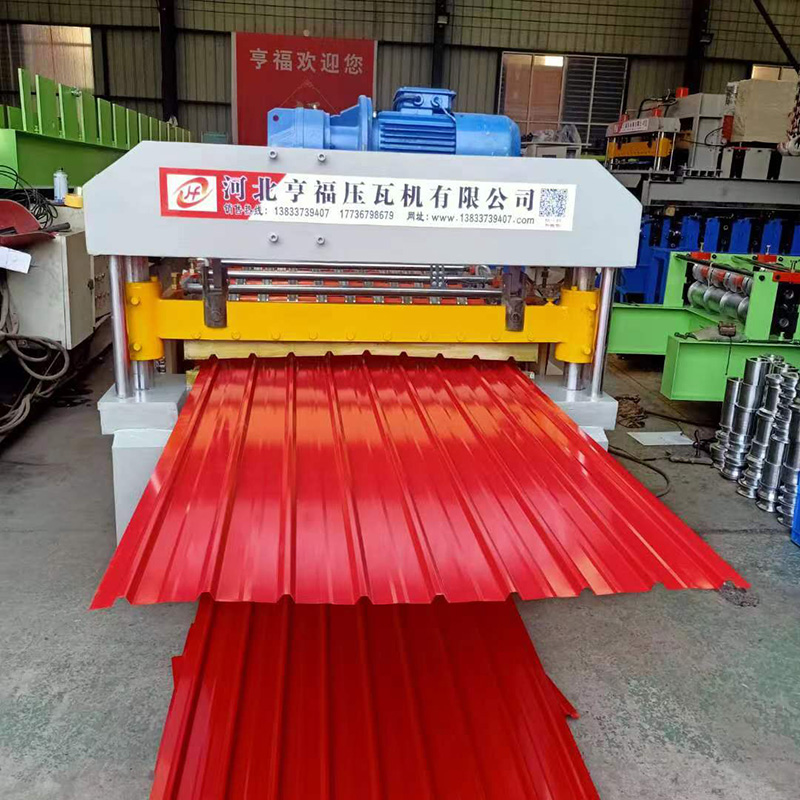

828 Roll Forming Machine

Main technical parameters of 828 roll forming machine(1) Applicable plates: Material: color-coated plate, yield strength 235 MPa.

Main technical parameters of 828 roll forming machine

(1) Applicable plates: Material: color-coated plate, yield strength 235 MPa

(2) Applicable plate thickness: 0.25---0.8mm

(3) Raw material width: 1000mm

(4)Production line speed: 0----8m/min

(5) Number of roller rows: 9 rows

(6) Roller shaft diameter: Φ70mm

(7) Overall dimensions: 6200mm×1300mm×1200mm

(8) Weight: 3.8T

(9)Power: 3kw

(10) Installation area: 828mm

Overview of the production process and configuration of the 828 roll forming machine

Production process flow: unloading----steel plate forming----forming hydraulic cutting----discharging rack

828 roll forming machine equipment consists of:

1. Ordinary unwinding stand

2. Feed import platform

3. Steel plate forming host

4. Glaze pressing machine

5. Steel plate forming and shearing device

6. Hydraulic system

7. Computer control cabinet

8. Counter

9. Discharge receiving rack

828 roll forming machine includes a forming host, a hydraulic station, a discharge rack, a forming shear, a control box, and a discharge rack. The production process of 828 roll forming machine: uncoiling - correctly feeding the forming or feeding shaft - measuring the length - plate pressing - cutting to length - discharging the finished product. The antique glazed tiles rolled and punched by 828 roll forming machine have the characteristics of beautiful appearance, simple and elegant, elegant and unique shape, etc., and can be widely used in garden-style factories, tourist attractions, pavilions, hotels, villas, exhibition halls, resorts , homes and other buildings and outdoor decoration.

The characteristics of 828 roll forming machine equipment are:

1. It is water-proof, heat-insulating, sound-insulating, beautiful, environmentally friendly, colorful, and colorful. It can be produced according to the user's requirements and is enough to meet people's different pursuits of beauty.

2. Economical, practical and low price. The price is close to that of small green tiles. One glazed tile is equivalent to 18 to 20 small green tiles. A room requires 4000 to 5000 small green tiles. It only costs 220 to 240 small glazed tiles to cover. The price of building a glazed tile is more than 100 yuan more than building a small green tile, which is affordable to ordinary people.

3. The glazed tile press equipment is made of new composite materials, cement, and sand and gravel. It is strong, durable, and pressure-resistant. When someone stands on the tile, nothing will be lost. It can be nailed and pasted during construction. Once it is covered, it will never be lost. Flip the cover and enjoy it for life, eliminating the loss and labor caused by frequent flipping of the small green tile house and leakage.

4. Light weight, convenient and simple construction. The weight of 18-skin small green tile is about 12 kilograms, and the weight of l-skin glazed tile is about 8 kilograms. Each room reduces the load-bearing capacity by 800 to 900 kilograms, extending the service life of the house.

5. The design is scientific and reasonable, and it will never leak. There are two vertical and horizontal waterproof lines, the surface is flat and smooth, and the rainwater will flow away obediently.

The 828 roll forming machine is divided into three parts, the roller forming part, the pressing part and the cutter part. The roller forming part is driven by a motor, and the chain drives each roller to rotate. In the pressing part, a hydraulic cylinder drives the mold to move up and down, which can press the colored steel into many sections, shaped like glazed tiles. The cutter part is a hydraulic cylinder that drives the cutter to move up and down, which can cut off the colored steel tiles. The production process of the 828 roll forming machine is as follows: the colored steel plate enters the roller forming part. After forming, it goes to the pressing part and is pressed into equidistant sections. The cutter is responsible for cutting to a fixed length.

Dongguang County Hengfu Roll Forming Machinery Co.,Ltd is a professional high-end cold roll forming equipment manufacturer integrating independent research and development, production, sales and service. Our company has long been committed to the development of cold bending and roll forming. Product quality is stable, cost-effective, excellent design engineers and good processing technology ensure the quality and performance of the equipment, and have passed various quality system certifications, and have a complete and scientific quality management system. The products designed and manufactured by us are not only sold well in China, but also exported to Southeast Asia, the Middle East,South America, North America, Europe and other countries and regions, and have won wide acclaim and praise!

Our company can produce various types of tile pressing machine products, and the roll forming plate types are diverse.

QC Profile

All the roll forming machines produced by our KYT Machinery have ourselves strict standard quality control process:

Parts Inspection

Machine Frames

Depends on roll forming machine’s size , we have 20#, 35#, 45# and may other bigger sizes H-beam for choise, after blasting and derusting, we weld each pieces of H-beam and then polish the weld place, finally paint whole roll forming frame together.

Rolling Shaft

45# forged steel or 40Cr, thermal refining and finishing lathe.

Forming Rollers

45# Steel,CNC lathes, fine polished, coat hard Chrome thickness 0.02-0.05mm for anti-rust and improve forming rollers'hardness. All the forming rollers will be spot inspected before installation.

Cutting Blades

The cutting blades material can be Cr12,C12Mov or SKD11 for our kinds of roll forming machines.Before cutting blades be installed on cutting frame, the hardness will be tested for ensure the using life.

Whole Roll Forming Line Inspection

Check the whole line each parts are on list or not at first, then adjust the roll forming machines to required dimensions to get correct roll forming samples, check the roll forming samples surface, dimensions according to design drawing, even two pieces sample joint effect. If not reached the required standard, the engineer will adjust whole machine to solve the problem together with our designer.