Differences Between Scissors Guide Rail and Guide Post Movement

writer:Hengfu release time:2024-08-22 10:18:26 Views:102frequency

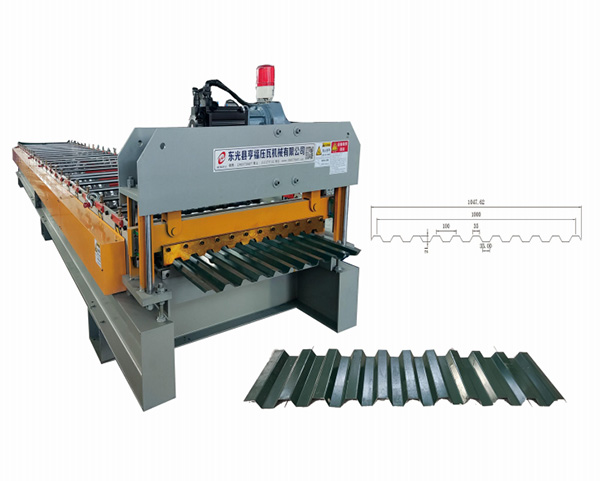

When it comes to cutting products with the scissors of a tile press, two common methods are used: the guide post and the guide rail. Both methods can effectively perform the cutting function, but they operate differently and have distinct characteristics.

1. Guide Post Method

The guide post method typically refers to a hydraulic guide post system. This system uses cylindrical guide posts that move up and down to drive the scissors for cutting. Key features include:

Movement: Hydraulic guide posts are driven by hydraulic cylinders, which operate based on signals sent from a PLC. As a result, the response speed of the guide post is relatively slow.

Speed: The hydraulic system's reliance on PLC control and the hydraulic cylinder’s operation leads to a slower overall cutting speed.

Cutting Effectiveness: Variations in hydraulic pressure on either side of the guide posts can result in cutting discrepancies. Although the speed is slower and the cutting effect may be average, the guide post method still meets basic cutting needs.

2. Guide Rail Method

The guide rail method generally refers to an electric guide rail system. This system uses electric guide rails to move up and down, driving the scissors for cutting. Its characteristics include:

Movement: Electric guide rails are controlled directly by motors, providing quick and efficient movement of the scissors.

Speed: The direct motor drive ensures a faster cutting speed compared to hydraulic systems.

Cutting Effectiveness: The guide rail system maintains a stable and horizontal cutting path, ensuring balanced movement. Compared to the guide post method, the guide rail system produces cuts with fewer or no burrs, cleaner edges, and less likelihood of wrinkles, thus enhancing product appearance and quality.

Summary

The guide post method, suited for hydraulic cutting systems, offers simplicity but with slower response and average cutting quality. In contrast, the guide rail method, typically used in servo-electric cutting systems, delivers faster cutting speeds and superior cutting quality, making it ideal for applications requiring high precision and speed. Choosing the right movement method can significantly improve cutting efficiency and product quality.

Elevate Your Cutting Performance with Our Advanced Solutions!

Discover the difference high-quality guide rail and guide post systems can make in your production line. Whether you need the dependable performance of hydraulic systems or the rapid precision of electric guide rails, we offer state-of-the-art solutions tailored to your specific needs. Our expert team is here to help you select the perfect system to enhance your productivity and achieve impeccable cutting results.

Contact us today for a consultation and experience the superior performance of our cutting solutions!

Andy