Working Principles and Operation Guide of Square Ridge Roll Forming

writer:Hengfu release time:2024-10-21 13:49:06 Views:152frequency

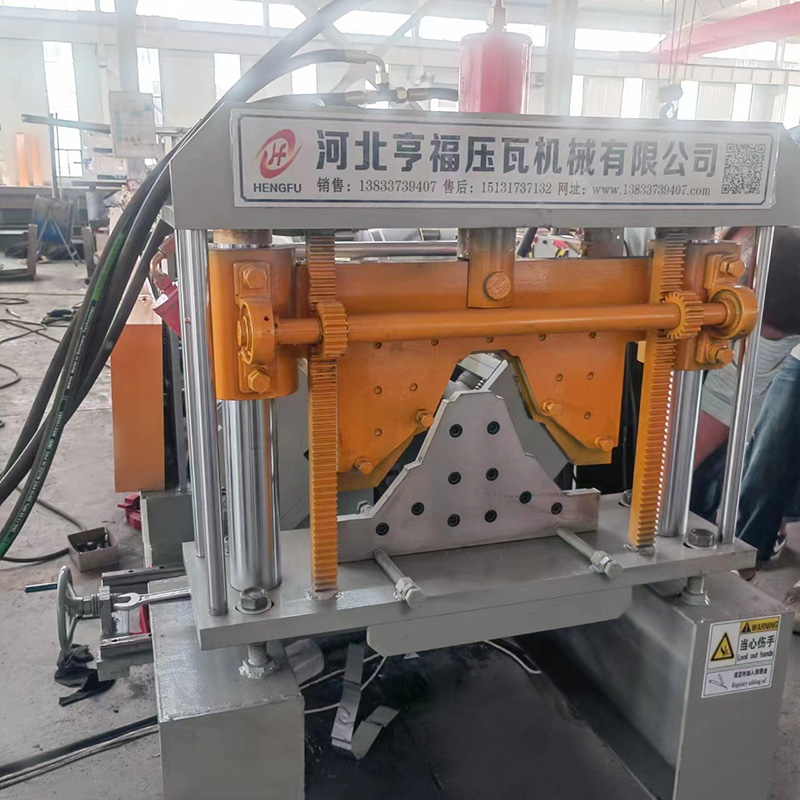

The square ridge roll forming is a specialized machine used for manufacturing square ridge tiles, which play a dual role in roofing systems by enhancing aesthetics and providing protection. These tiles are particularly suitable for decorative and leak-proof applications on sloped roofs. This article delves into the working principles and operation guide of the square ridge roll forming, helping users maximize efficiency and product quality in their production processes.

1. Working Principles of the Square Ridge Roll Forming

The square ridge roll forming uses mechanical or hydraulic pressure to shape metal materials, such as color-coated steel sheets, into pre-designed square ridge tiles. The basic working process is as follows:

1. Material Preparation: Place pre-treated metal sheets or color steel plates on the machine’s feeding platform, ready for the pressing process.

2. Feeding Process: The press automatically feeds the material into the pressing area, ensuring the sheet is flat and aligned for precise shaping.

3. Tile Forming: Using a die within the machine, the material is pressed into the specific shape of the square ridge tile. The machine applies uniform pressure, bending the metal sheet along pre-set curves to create tiles that meet design specifications.

4. Cutting and Shaping: After forming the tiles, the machine automatically cuts the material to ensure consistent size and smooth edges.

5. Finished Product Output: The pressed square ridge tiles are then ejected from the machine, ready for further handling by workers or automated systems.

2. Operation Guide for the Square Ridge Roll Forming

To ensure the machine operates efficiently and safely, operators must strictly follow the recommended operating procedures. Below is a step-by-step guide to help users fully utilize the machine’s capabilities.

1. Preparation Before Operation

Check Power and Hydraulic System: Ensure the power is correctly connected, the hydraulic system is functioning properly, and the hydraulic oil level is within the required range.

Die Inspection: Inspect the press dies to confirm they are in good condition, as worn or damaged dies can affect the quality of the tiles.

Material Preparation: Ensure the steel plates or metal sheets are flat, free of visible scratches, and suitable for the pressing process.

2. Operation Steps

Start the Machine: Follow the startup procedure outlined in the machine’s manual, powering up the system, hydraulic components, and control systems to ensure smooth operation.

Set Parameters: Use the control panel to set the tile dimensions, pressing angle, working pressure, and speed to meet production requirements.

Begin Pressing: Place the material accurately into the machine, activate the feeding system, and let the automatic process feed the material into the dies for pressing.

Inspect Product Quality: After the pressing process, inspect the square ridge tiles for size accuracy, form quality, and cutting precision to ensure each tile meets the required standards.

3. Maintenance and Care

Daily Cleaning: After each workday, clean the machine, particularly the dies and feeding platform, to remove any debris that could affect future production.

Regular Inspections and Lubrication: Periodically inspect the machine’s mechanical and hydraulic components, lubricating moving parts to ensure smooth operation.

Die Maintenance: Since the dies are critical components of the square ridge roll forming, regularly check for wear and replace or repair them as needed to maintain consistent tile quality.

3. Advantages of the Square Ridge Roll Forming

High Production Efficiency: The machine’s fully automated operation significantly boosts production efficiency, enabling rapid production of large quantities of square ridge tiles.

High-Quality Finished Products: The press uses precise molds and consistent pressure to produce accurate and aesthetically pleasing ridge tiles, meeting the demands of architectural applications.

User-Friendly Operation: Equipped with an intelligent control system, the machine is easy to operate, even for users with minimal experience, reducing operational complexity.

Cost Savings: The machine’s efficient production process minimizes material waste and labor costs, helping companies reduce their overall production expenses.

Conclusion

The square ridge roll forming is an indispensable piece of equipment in the construction industry, offering efficient and precise tile production capabilities. By following the operational guidelines outlined in this article, users can ensure the machine runs smoothly and consistently produces high-quality ridge tiles. Regular maintenance will further extend the machine’s lifespan, ensuring optimal performance over time.