In modern construction and roofing projects, an aerial roofing platform machine has become an essential tool. This equipment is widely used for tasks at heights, such as roofing tile installation, repair, and construction. Selecting the right aerial roofing platform machine can enhance work efficiency and ensure worker safety and project quality. This article introduces the best practices for choosing an aerial roofing platform machine to help you make an informed purchasing decision.

1. Understanding the Basic Functions of an Aerial Roofing Platform Machine

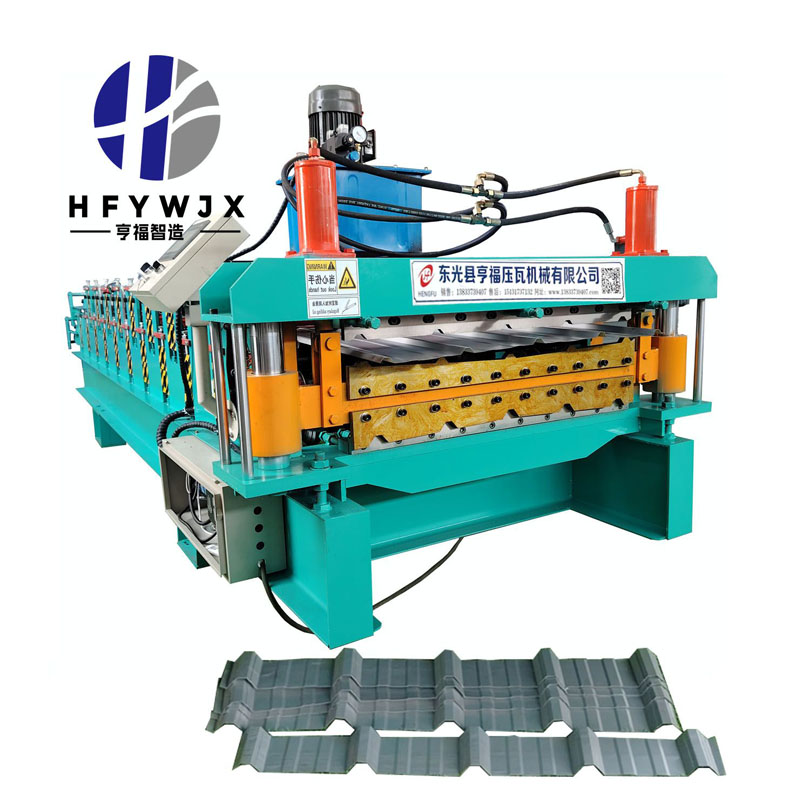

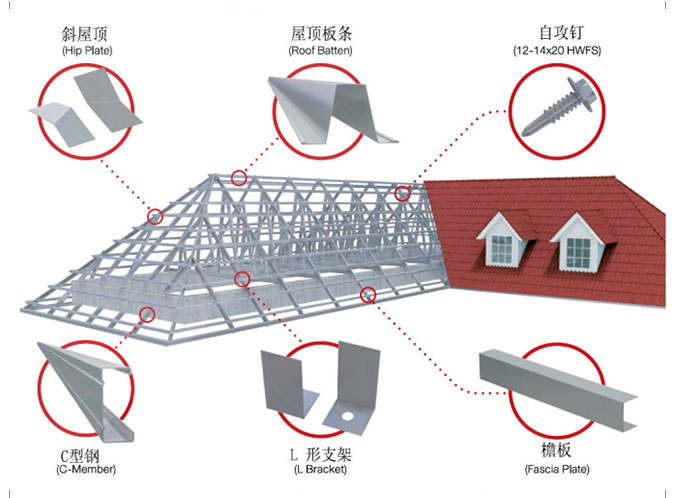

An aerial roofing platform machine is designed specifically for construction at heights, combining the functionalities of tile pressing and an aerial platform. It is commonly used for tile pressing and installation on roofs. The machine offers the following main functions:

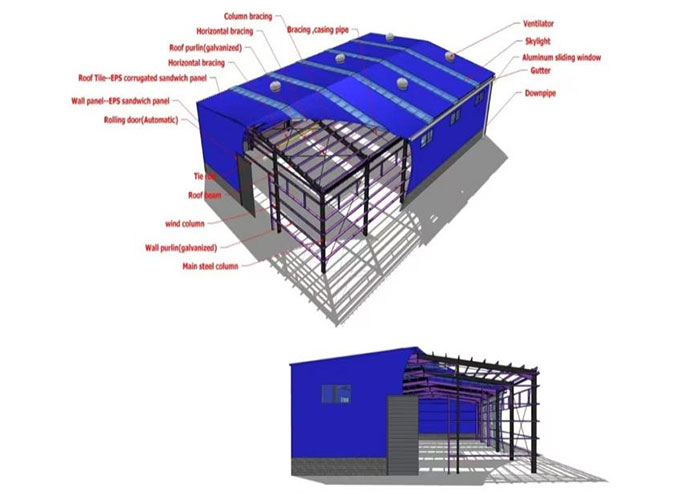

Aerial Work Platform: Provides a secure platform for workers to operate at roof height.

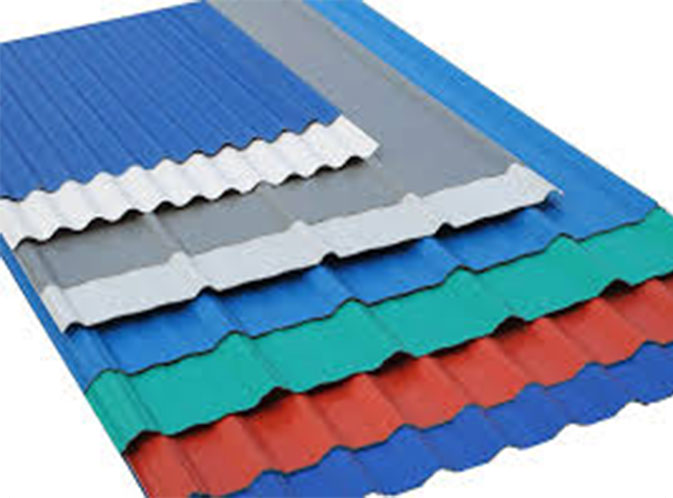

Tile Pressing Function: Uses precise mechanical systems to install tiles accurately on roofs.

Adjustability: Can be flexibly adjusted according to different roof angles and heights to suit various construction environments.

2. Key Factors for Choosing an Aerial Roofing Platform Machine

(1) Working Height and Load Capacity

When selecting an aerial roofing platform machine, consider the working height and load capacity first. Choose a machine that meets the height requirements of the project. The platform's load capacity must also be sufficient to support the weight of workers and tools to ensure safety.

Working Height: Ensure the machine can reach the required working height. Aerial machines typically have a range from several meters up to over ten meters.

Load Capacity: The platform's load capacity should accommodate the number of workers and the necessary equipment. Choose a machine with a high load capacity to ensure safe operation.

(2) Stability and Safety of the Equipment

Safety is crucial for aerial work, so selecting a stable and secure machine with multiple safety features is essential.

Anti-Tilt Design: The machine should have anti-tilt functionality to ensure platform stability during operation. Anti-tilt features are especially beneficial in high winds or unstable environments, greatly reducing the risk of accidents.

Safety Railings and Nets: Ensure the platform is equipped with guardrails and safety nets to protect workers from falling.

Automatic Braking System: Some aerial roofing platforms are equipped with automatic braking systems, which immediately stop the machine in case of emergencies, ensuring worker safety.

(3) Mobility and Flexibility of the Equipment

The aerial roofing platform machine often needs to move across different construction areas, so mobility and flexibility are important.

Wheel Design: Choose a machine with a robust wheel design that can move smoothly on various types of ground. Wheels make it easier to position the platform and facilitate movement on the construction site.

Adjustable Platform: Consider selecting a platform that can adjust its angle based on work requirements. An adjustable angle allows workers to operate more comfortably, ensuring construction quality and efficiency.

(4) Ease of Operation and Control System

Ease of operation is a key factor in choosing an aerial roofing platform machine. The platform should have an intuitive control system to reduce the risk of accidents caused by operational errors.

Remote Control Function: Some machines are equipped with remote control capabilities, allowing operators to control the equipment from a distance, avoiding complex operations at height and reducing safety risks.

User-Friendly Interface: The control system should be clear and straightforward, allowing operators to quickly learn and reduce the chance of operational errors.

3. Choosing the Brand and Quality of the Aerial Roofing Platform Machine

Choosing a high-quality machine ensures long-term stability and reduces the likelihood of malfunctions. When selecting a brand, consider the following aspects:

(1) Reputation and Reliability of the Brand

Opting for a well-known brand can reduce the risk of equipment failure and safety hazards. Renowned brands typically offer a strong after-sales service system and technical support for timely repairs and maintenance.

(2) Product Quality Certifications

A high-quality machine should have relevant quality certifications, such as CE or ISO9001. These certifications indicate compliance with international standards and guarantee safety and reliability.

(3) User Reviews and Case Studies

Reviewing feedback from other users and examining case studies can provide better insight into the equipment’s actual performance and reliability. Select brands and products that are widely acclaimed in the industry.

4. After-Sales Service and Maintenance Support

The long-term stability of an aerial roofing platform machine depends on reliable after-sales service and maintenance. Consider the following aspects when selecting equipment:

(1) Technical Support

Ensure the manufacturer can provide fast technical support. Technical support is essential for efficient operation, whether it involves equipment setup, usage training, or troubleshooting.

(2) Spare Parts and Repair Services

Since long-term use may require part replacements or repairs, choose a manufacturer that provides sufficient spare parts and repair services.

5. Energy Efficiency and Environmental Impact

With increasing environmental requirements, many companies are now paying attention to the energy efficiency and environmental impact of their equipment. When choosing an aerial roofing platform machine, also consider the equipment’s energy consumption and emissions.

Low Energy Consumption Design: Select machines designed for energy efficiency and low emissions, which helps reduce operating costs and benefits the environment.

Noise Control: The machine should operate at low noise levels to minimize impact on the work environment and surrounding residents.

6. Conclusion

Choosing a suitable aerial roofing platform machine can enhance productivity, ensure safety, and reduce operating costs. By considering factors such as platform working height, load capacity, stability, safety, ease of operation, brand reputation, and after-sales support, you can find the equipment that best meets your needs. We hope these recommendations will help you make an informed decision to improve work efficiency and ensure safety in aerial operations.