In the metal fabrication industry, roll forming machines are vital tools that streamline the production of metal components. One of the most commonly used machines is the downspout roll forming machine, which is designed to produce downspouts, a key element in rainwater drainage systems for buildings. Whether you're producing downspouts for residential, commercial, or industrial properties, a downspout roll forming machine offers precision, efficiency, and versatility, allowing manufacturers to meet the high demand for quality downspouts in various applications. In this blog, we will explore the features, benefits, and uses of the downspout roll forming machine.

1. What is a Downspout Roll Forming Machine?

A downspout roll forming machine is a specialized piece of equipment used to manufacture metal downspouts from steel coils. Downspouts are integral parts of gutter systems that direct rainwater from the gutters down to the ground, preventing water damage to buildings. The roll forming machine is designed to create downspouts in various shapes and sizes, with the most common being round, square, and rectangular profiles.

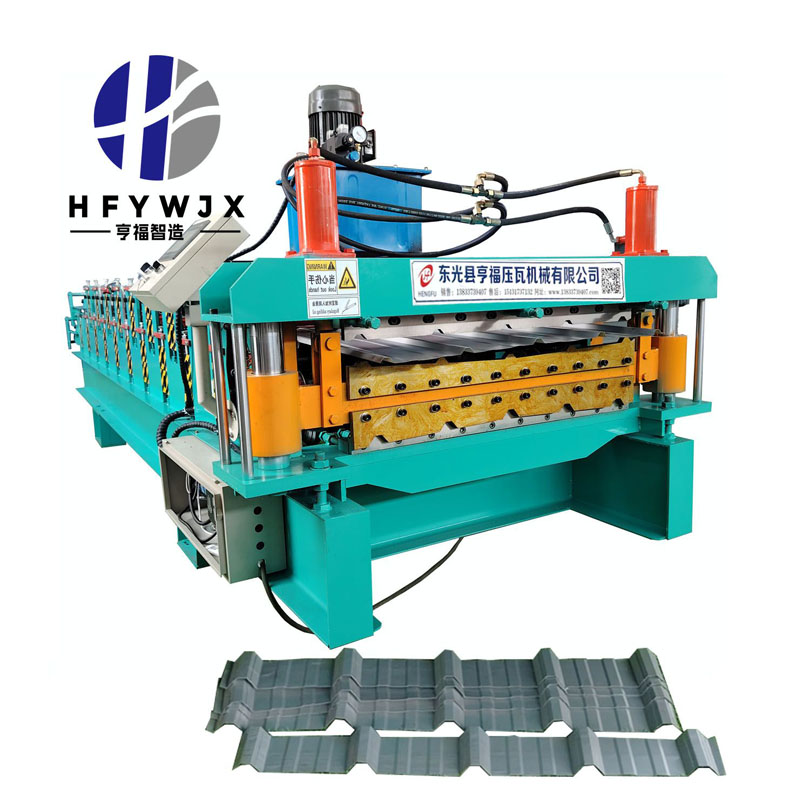

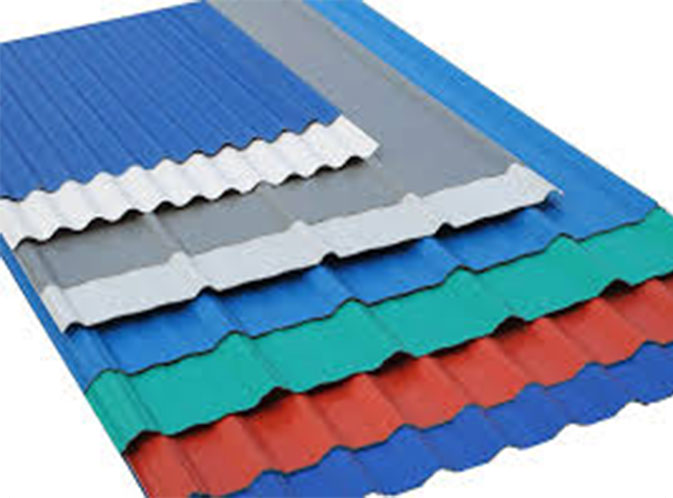

The downspout roll forming machine works by feeding a coil of metal (typically galvanized steel, aluminum, or stainless steel) through a series of rollers that progressively shape the metal into the desired profile. The machine can also incorporate features such as holes for downspout brackets, joints, and seams, ensuring the finished product is ready for installation.

2. How Does a Downspout Roll Forming Machine Work?

The process of using a downspout roll forming machine typically involves several key steps to ensure the production of high-quality downspouts:

(1) Feeding the Metal Coil

The process starts with the feeding of a steel coil into the machine. The coil is unrolled and aligned to ensure it moves through the rollers smoothly, without causing any defects or distortions in the metal.

(2) Roll Forming Process

As the metal coil moves through the machine, it passes through a series of rollers. These rollers progressively shape the metal into the desired profile. For downspouts, the machine can produce a variety of shapes, including round, square, or rectangular sections, based on the project requirements.

(3) Adding Holes or Joints

Depending on the design, the roll forming machine can be equipped with additional tools to create holes for mounting brackets, screws, or other fastening mechanisms. It can also add seams or joints for easy connection with other downspout sections.

(4) Cutting the Downspout

Once the metal has been formed into the downspout profile, the machine automatically cuts it to the desired length. The cutting mechanism is synchronized with the forming process to ensure accuracy and efficiency.

(5) Final Output

After the downspout is formed and cut, it is discharged from the machine, ready for use. The automation of the process ensures that each downspout is made with consistent dimensions, reducing the chances of defects and improving the overall quality of the final product.

3. Key Features of a Downspout Roll Forming Machine

Modern downspout roll forming machines come with a variety of advanced features that improve their functionality and efficiency:

(1) High Precision

One of the key features of a downspout roll forming machine is its ability to produce downspouts with precise dimensions. Whether you are making round, square, or rectangular downspouts, the machine ensures consistent quality and accuracy in every piece.

(2) Adjustable Settings

Many machines offer adjustable settings, which allow operators to easily modify the size, profile, and length of the downspouts being produced. This flexibility ensures that the machine can be used for a wide range of applications and custom orders.

(3) Fast Production Speed

High-quality downspout roll forming machines are designed for efficiency, capable of producing large volumes of downspouts quickly. The high-speed operation reduces downtime and increases overall production output, which is essential for meeting tight project deadlines.

(4) Durability and Reliability

Downspout roll forming machines are built to last. They are made from high-quality materials and engineered to handle continuous operation without frequent breakdowns or maintenance, offering long-term reliability for manufacturers.

(5) Automation

Most downspout roll forming machines are fully automated, reducing the need for manual intervention. Automated features like automatic cutting, punching, and stacking help streamline production, improving efficiency and reducing labor costs.

4. Benefits of Using a Downspout Roll Forming Machine

The use of a downspout roll forming machine offers numerous benefits for manufacturers and construction companies:

(1) Increased Efficiency

By automating the production process and allowing for fast and precise manufacturing, the downspout roll forming machine significantly increases production efficiency. Manufacturers can produce large quantities of downspouts in a shorter time, making it easier to meet customer demand and project deadlines.

(2) Cost-Effective Manufacturing

Using a roll forming machine reduces the need for manual labor and minimizes material waste, which leads to cost savings. The high precision of the machine ensures that each downspout is made to exact specifications, reducing the risk of defects and the need for rework.

(3) Consistent Quality

With a downspout roll forming machine, manufacturers can ensure that every downspout is produced to consistent quality standards. The automation and precision of the machine help eliminate errors that can occur during manual fabrication, resulting in uniformity across every unit.

(4) Customization

A downspout roll forming machine offers flexibility in terms of customization. Operators can adjust the machine to produce downspouts in a range of profiles and sizes to meet specific project requirements. Whether it’s for residential or commercial applications, the machine can be tailored to produce custom profiles and lengths.

(5) Reduced Labor Costs

The automation of the roll forming process reduces the need for manual labor, saving businesses on labor costs. Additionally, the machine’s ability to quickly change profiles and adjust settings minimizes downtime and further enhances productivity.

5. Applications of Downspout Roll Forming Machines

Downspout roll forming machines are used in a variety of industries and applications:

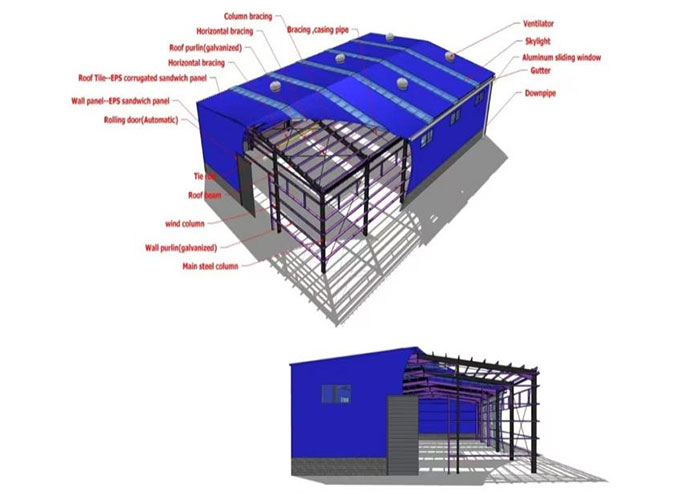

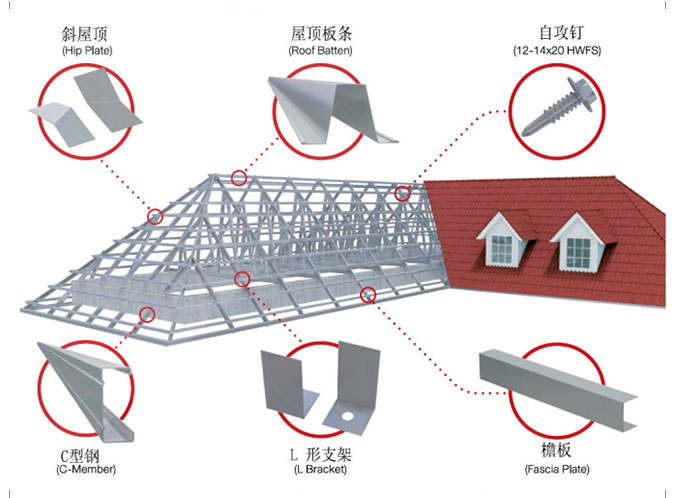

(1) Residential and Commercial Roofing

In both residential and commercial buildings, downspouts are essential for effective water drainage. These machines are used to produce the downspouts that are installed alongside gutter systems to channel rainwater safely away from the building’s foundation.

(2) Industrial Applications

Downspouts are commonly used in industrial buildings and factories, where effective water management is necessary to protect the structure from water damage. The roll forming machine produces downspouts that meet the demands of heavy-duty industrial applications.

(3) Agricultural Buildings

In agricultural settings, such as barns and silos, downspouts help manage rainwater runoff and prevent flooding. The roll forming machine can create downspouts tailored to the specific needs of these types of buildings.

(4) Stormwater Management

Municipalities and commercial properties rely on downspouts for stormwater management. The downspout roll forming machine ensures that these vital components are produced quickly and efficiently, helping to manage rainwater in large-scale drainage systems.

6. Conclusion

The downspout roll forming machine is a valuable tool for manufacturers looking to produce high-quality downspouts efficiently and cost-effectively. With its precision, speed, and versatility, this machine ensures that downspouts are made to exact specifications, reducing errors and improving overall production efficiency. Whether you’re working on a residential, commercial, or industrial project, investing in a downspout roll forming machine can streamline your production process and help you meet the growing demand for reliable drainage systems.